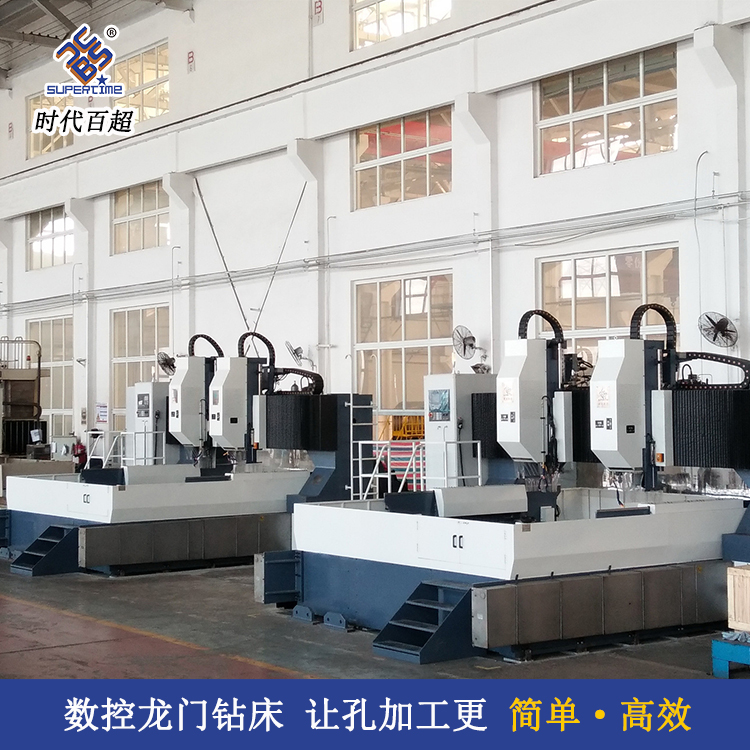

产品专柜

▲CAD/CAM直接转换,实现自动化,高精度加工。

▲主轴箱采用树脂砂造型的高清度铸铁以及合理的布筋结构,刚性好,稳定性强。

▲床身两侧面各装有高承载力直线滚动导轨副,龙门的纵向移动通过AC伺服电机双侧同步驱动。

▲选用品质优异的进口主轴组,具有超强的大扭矩输出能力,主轴采用同步带轮形式。

▲龙门横梁上装有1-4个可移动溜板,溜板采用两条滚动导轨副导向,驱动分别采用AC伺服电机和精密大螺距滚珠丝杠副传动。

▲电气系统:本机床数控系统采用西班牙FAGOR8055系统,并配有RS232接口和LCD液晶显示屏,钻孔坐标可实现CAD/CAM直接转换,并配备钻孔前孔位预演和复位功能,操作十分方便。

Q:怎样选择龙门移动式平面钻设备?

A:济南时代百超科技有限公司和济南硕超数控设备有限公司的板材加工设备有冲孔机床,钻孔机床,冲钻复合机,冲割复合机,冲钻复合机。

1.根据工作台的宽度大小分龙门单侧驱动和龙门双侧同步驱动两种驱动方式,一般在加工有效工件宽度大于1600mm,采用龙门双侧同步驱动, 龙门双侧同步驱动的有点是解决了大跨度龙门偏载的问题,保证了机床的X轴和Y轴的垂直度

2.根据龙门和工作台的连接方式分龙门平铺式和龙门侧挂式,GZP系列是龙门平铺式,GZC,CJ系列是龙门侧挂式。

龙门侧挂式采用床身和工作台一体式结构,结构紧凑占地面积小,安装方便,造价低。

龙门高架式的床身和工作台是分开的,且都采用优质铸铁件,这种结构可以灵活的改变主轴端面到工作台的距离,机床刚性强,精度稳定可靠。

龙门高架式(GZP系列)可进行铣削加工和攻丝,龙门侧挂式(GZC系列)只有钻孔和轻铣槽的功能。

龙门高架式的价格要比龙门侧挂式价格要高。

3.根据加工的板材大小决定, 如:加工2000mmX1500X40mm的板材可以选择CJ2016Z,该机可以最大加工2000mmX1600mmX80mm的材料。可以选用双工作台移动式设备,在加工小件时 提高设备的利用率

4.根据钻孔的孔径选择, 常规的CJ系列设备加工的最大孔径为D50mm,根据用户的要求DZC,GZC,GZP系列可以加工到D90的孔径

5.根据板材上孔的数量和加工孔的精度可以选择高速钻或者低速钻,高速钻的转速可以达到3000rpm,提高钻孔的效率。

6.常用的钻的规格有:1610,2016,3016,1616,2020,2525,3030,4040,4030,5050,6060,7060,7070,8080,9090等规格,2525以上的规格一般可以配置2-4个动力头,最多可以配置12个动力头,提高钻孔的效率和设备的利用率。

7.需要用户注意的就是,高速钻需要配置合金高速钻头,这样可以大大提高生产效率,普通钻可以选标准的麻花钻头,经济实用。

8.控制系统是否支持ERP系统时代百超公司和硕超数控公司生产的数控设备全部提供ERP系统接口,可以实时读取ERP计划,并且实时上报加工数据到ERP系统,提高计划的响应性。

适用于时代百超公司设计和生产的CJ系列,GZP系列,GZC系列,GZG系列,DZCD系列,DZC系列龙门移动式平面钻,龙门钻,数控平面钻,龙门移动式数控平面钻的选型。

技术参数Specification

|

项 目 Item |

单位 Units |

GZC30 |

GZC40 |

GZC50 |

GZC60 |

||

|

工作台 Workstable |

工作台尺寸(宽×长) Workstable size |

mm |

3000×3000-24000 |

4000×4000-24000 |

5000×5000-24000 |

6000×6000-24000 |

|

|

两立柱间距 Distance between columns |

mm |

3800 |

4800 |

5800 |

6800 |

||

|

工作台承重 Max.load capacity |

t/m² |

7 |

7 |

7 |

7 |

||

|

T型槽宽度 T-slot |

mm |

28 |

28 |

28 |

28 |

||

|

垂直滑枕式 动力头 Vertical ram type drilling head |

数量 Quantity |

个Pieces |

2标配 |

2标配 |

2标配 |

2标配 |

|

|

主轴锥孔 Taper hole of spindle |

BT50 |

BT50 |

BT50 |

BT50 |

|||

|

最大钻孔直径 Max. drilling diameter |

mm |

φ60 |

φ60 |

φ60 |

φ60 |

||

|

钻孔深度/钻孔直径Drilling depth/diameter |

≤5(硬质合金钻头) (Carbide drill) |

≤5(硬质合金钻头) (Carbide drill) |

≤5(硬质合金钻头) (Carbide drill) |

≤5(硬质合金钻头) (Carbide drill) |

|||

|

主轴转速 Spindle rotation speed |

r/min |

30—3000标配 |

30—3000标配 |

30—3000标配 |

30—3000标配 |

||

|

主轴伺服电机功 Spindle motor power |

kW |

22/33标配 |

22/33标配 |

22/33标配 |

22/33标配 |

||

|

主轴最大扭矩(n≤600r/min) Max. spindle torque |

Nm |

350标配 |

350标配 |

350标配 |

350标配 |

||

|

主轴下端面到工作台面距离 Distance between spindle and Workstable |

mm |

280-780标配 |

280-780标配 |

280-780标配 |

280-780标配 |

||

|

龙门纵向移动 (X轴) Longitudinal Movement of Gantry |

最大行程 Max.stroke |

mm |

3000-24000 |

4000-24000 |

5000-24000 |

6000-24000 |

|

|

X轴移动速度 Moving speed of X axis |

m/min |

0-10 |

0-10 |

0-10 |

0-10 |

||

|

X轴伺服电机功率/扭矩 servo motor power/ torque |

kW/ Nm |

3/28.4 |

3/28.4 |

3/28.4 |

3/28.4 |

||

|

动力头横向移动(Y轴) Transverse Movement of Drilling head |

最大行程 Max.stroke |

mm |

3000 |

4000 |

5000 |

6000 |

|

|

Y轴移动速度 Moving speed of Y axis |

m/min |

0-10 |

0-10 |

0-10 |

0-10 |

||

|

Y轴伺服电机功率/扭矩 servo motor power/ torque |

kW/ Nm |

3/28.4 |

3/28.4 |

3/28.4 |

3/28.4 |

||

|

垂直滑枕进给运动(Z轴)Feeding of Vertical ram |

行程 stroke |

mm |

500 |

500 |

500 |

500 |

|

|

Z轴进给速度 Moving speed of Z axis |

m/min |

0-5 |

0-5 |

0-5 |

0-5 |

||

|

Z轴伺服电机功率/扭矩 servo motor power/ torque |

kW/ Nm |

3/28.4 |

3/28.4 |

3/28.4 |

3/28.4 |

||

|

项 目 Item |

单位 Units |

GZC30 |

GZC40 |

GZC50 |

GZC60 |

||

|

定位精度 Positioning precision |

X轴 X axis |

mm |

0.06/2000 |

0.06/2000 |

0.06/2000 |

0.06/2000 |

|

|

带光栅0.03/2000 With optical scale |

带光栅0.03/2000 With optical scale |

带光栅0.03/2000 With optical scale |

带光栅0.03/2000 With optical scale |

||||

|

Y轴 Y axis |

mm |

0.08/全长 |

0.08/全长 |

0.1/全长 |

0.1/全长 |

||

|

带光栅0.04/全长 With optical scale |

带光栅0.04/全长 With optical scale |

带光栅0.05/全长 With optical scale |

带光栅0.05/全长 With optical scale |

||||

|

重复定位精度 Re-positioning precision |

X轴 X axis |

mm |

0.03/2000 |

0.03/2000 |

0.03/2000 |

0.03/2000 |

|

|

带光栅0.015/2000 With optical scale |

带光栅0.015/2000 With optical scale |

带光栅0.015/2000 With optical scale |

带光栅0.015/2000 With optical scale |

||||

|

Y轴 Y axis |

mm |

0.04/全长 |

0.04/全长 |

0.05/全长 |

0.05/全长 |

||

|

带光栅0.02/全长 With optical scale |

带光栅0.02/全长 With optical scale |

带光栅0.025/全长 With optical scale |

带光栅0.025/全长 With optical scale |

||||

|

液压系统Hydraulic systerm |

液压泵压力 Hydraulic pump pressure |

MPa |

6.5 |

||||

|

液压泵流量 Hydraulic pump flux |

L/min |

25 |

|||||

|

液压泵电机功率 Motor power of pump |

kW |

3 |

|||||

|

排屑 Swarf cleaner |

排屑器型式 Type of Swarf cleaner |

平板链式Plate chain type |

|||||

|

排屑器数量 Quantity of swarf cleaner |

个Pieces |

2 |

|||||

|

排屑速度 Swarf cleaning speed |

m/min |

1 |

|||||

|

排屑器电机功率 Motor power |

kW |

2X0.75 |

|||||

|

冷却 Cooling systerm |

内冷水泵电机功率Motor power of inner |

kW |

2×3 |

||||

|

外冷水泵电机功率Motor power of outer |

kW |

0.75 |

|||||

|

自动润滑系统 Centralized lubrication |

润滑压力 Pressure |

MPa |

2 |

||||

|

润滑点注油量 Oiling quantity |

mL |

0.1 |

|||||

|

电气系统Electrical systerm |

数控系统 CNC systerm |

FAGOR8055 |

|||||

|

数控轴数 No.of CNC |

6 |

||||||

|

电机总功率 Total motor power |

kW |

约(About)90 |

|||||